Motor torque specifications directly impact acceleration, hill-climbing capability, and overall riding satisfaction. Unlike traditional power ratings measured in watts, torque provides the rotational force that propels your e-bike forward, making it the most critical technical specification for serious riders. This comprehensive guide explores everything you need to know about e-bike motor torque, from basic principles to advanced technical considerations.

Understanding E-Bike Motor Torque Fundamentals

What Is Motor Torque in Electric Bikes?

Motor torque represents the rotational force generated by an electric motor to drive the wheels forward. Measured in Newton-meters (Nm), torque determines how much twisting force the motor applies to overcome resistance and propel the bike. Unlike power (measured in watts), which relates to sustained energy output, torque provides the immediate force needed for acceleration and climbing.

In practical terms, higher torque ratings translate to more responsive acceleration from standstills, superior hill-climbing performance, and enhanced load-carrying capacity. Modern e-bike motors typically range from 30Nm for lightweight urban models to 90Nm or higher for high-performance mountain bikes. The Movcan lineup strategically incorporates different torque specifications across models to optimize performance for specific riding applications.

The Science Behind Torque vs. Power Ratings

The relationship between torque and power in e-bike motors follows the fundamental physics equation: Power = Torque × Angular Velocity. This means that at lower speeds (such as starting from a stop or climbing steep hills), torque becomes the dominant performance factor. Conversely, at higher speeds, power ratings become more significant for maintaining velocity against aerodynamic resistance.

Electric motors deliver maximum torque immediately upon activation, unlike internal combustion engines that require higher RPMs to reach peak torque. This characteristic gives e-bikes their distinctive "instant acceleration" feel and explains why even 250W e-bike motors can outperform much more powerful gas engines in stop-and-go urban environments.

Technical Specifications Across Riding Categories

Urban Commuting Requirements (35-50 Nm)

Urban commuting demands moderate torque specifications that balance acceleration with battery efficiency. The Movcan V80 Commuting Electric Bike exemplifies this category with its optimized torque output designed for city riding conditions. This torque range provides adequate force for navigating traffic, moderate hills, and frequent stop-and-start scenarios typical of urban environments.

For daily commuters, torque specifications in this range offer several advantages: smooth acceleration from traffic lights, sufficient power for bridge climbs and moderate inclines, and extended battery life due to efficient power delivery. The key technical consideration is maintaining consistent assistance without overwhelming the rider or draining the battery excessively.

Off-Road and Mountain Applications (70-90+ Nm)

Mountain biking and off-road applications require significantly higher torque specifications to handle steep climbs, technical obstacles, and varied terrain conditions. The Movcan EB60 Electric Mountain Bike and V60 Pro Electric Bike models incorporate high-torque motor systems designed for demanding off-road performance.

High-torque specifications enable riders to maintain momentum over technical terrain, power through loose surfaces, and tackle extreme gradients without motor stalling. The additional rotational force also supports heavier loads, such as carrying gear for extended trail adventures or bikepacking expeditions.

Dual Battery High-Performance Systems

The Movcan V30 Pro Max Dual Battery Electric Bike represents the pinnacle of torque engineering with its dual motor configuration. This advanced system delivers exceptional torque output while maintaining extended range through intelligent power management. Dual battery systems support higher peak torque ratings without compromising long-distance capability.

Technical advantages include redundant power delivery for enhanced reliability, increased total torque output for extreme performance applications, and sophisticated battery management systems that optimize torque distribution based on riding conditions.

Motor Types and Torque Characteristics

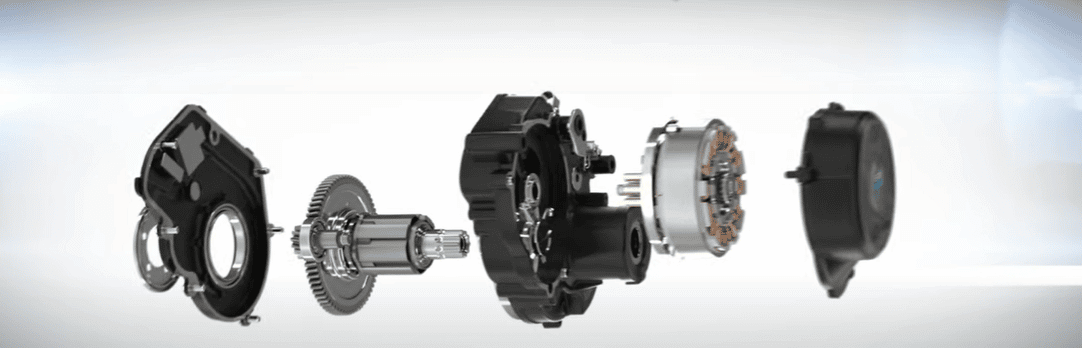

Mid-Drive Motor Advantages

Mid-drive motors excel in torque delivery efficiency by utilizing the bike's existing drivetrain. This configuration multiplies motor torque through the bike's gear system, effectively increasing the available torque at the wheel. The Movcan V40 Electric Bike utilizes mid-drive architecture to maximize climbing performance while maintaining balanced weight distribution.

Mid-drive systems provide natural torque multiplication through gear ratios, enhanced climbing efficiency on steep terrain, and better weight distribution for improved handling characteristics. The technical implementation requires precise motor-to-drivetrain integration and sophisticated control algorithms to prevent excessive chain wear.

Hub Motor Torque Delivery

Hub motors deliver torque directly to the wheel without drivetrain multiplication. The Movcan V30 Max and V60 series utilize advanced hub motor designs that optimize torque delivery for specific applications. Hub motors provide direct power transfer with minimal mechanical complexity and consistent torque output regardless of gear selection.

Hub motor advantages include simplified maintenance requirements, direct wheel drive without drivetrain stress, and consistent torque characteristics across all gear ratios. Technical considerations involve motor placement (front vs. rear hub) and cooling requirements for sustained high-torque operation.

Advanced Technical Considerations

Torque Sensors and Control Systems

Modern e-bike torque control relies on sophisticated sensor technology that measures rider input and adjusts motor assistance accordingly. Torque sensors detect pedaling force and modulate motor output to provide proportional assistance. This creates a natural riding feel where increased pedaling effort results in proportionally higher motor torque.

Advanced torque sensor systems incorporate strain gauges, magnetic sensors, and accelerometers to provide precise torque measurement and responsive motor control. The integration of these systems determines the quality of the riding experience and the efficiency of power delivery.

Peak vs. Sustained Torque Ratings

Understanding the difference between peak and sustained torque ratings is crucial for evaluating real-world performance. Peak torque represents the maximum momentary force the motor can generate, typically during initial acceleration or short climbs. Sustained torque indicates the continuous force the motor can maintain without overheating or performance degradation.

The Movcan engineering team optimizes both peak and sustained torque characteristics across their model lineup. This ensures consistent performance during extended climbs while providing the instant response needed for urban riding scenarios.

Thermal Management and Torque Output

High-torque operation generates significant heat that must be managed to maintain consistent performance. Advanced cooling systems and thermal management protocols ensure motors can deliver rated torque output without thermal throttling. Effective thermal design enables sustained high-torque operation during demanding riding conditions.

Technical solutions include active cooling systems, heat-dissipating motor housings, and intelligent thermal monitoring that adjusts torque output to prevent overheating. These systems maintain optimal performance while protecting motor longevity.

Optimizing Torque for Different Terrain Types

Hill Climbing Performance Metrics

Torque requirements for hill climbing depend on several factors: rider weight, bike weight, gradient steepness, and surface conditions. Higher torque motors can maintain speed on steeper gradients while requiring less rider effort. Technical calculations consider the total system weight and desired climbing speed to determine optimal torque specifications.

For riders frequently encountering steep terrain, torque ratings above 70Nm provide significant advantages in climbing performance and rider comfort. The Movcan V30 Pro Max dual battery system excels in these demanding conditions with its enhanced torque output and extended range capability.

Load Carrying and Cargo Applications

Cargo carrying increases torque requirements proportionally to the additional weight. Commercial delivery applications and family cargo bikes benefit from higher torque specifications that maintain performance under load. The additional rotational force compensates for increased rolling resistance and maintains acceleration capability with heavy cargo.

Technical considerations include load distribution effects on handling, increased braking requirements, and extended range calculations under cargo loading conditions. Proper torque specification ensures safe and efficient operation across various loading scenarios.

Variable Terrain Adaptability

Mixed terrain riding requires versatile torque characteristics that adapt to changing conditions. Modern e-bike control systems adjust torque delivery based on terrain detection and rider input patterns. This adaptability ensures optimal performance across diverse riding environments without manual intervention.

Maintenance and Torque Specifications

Proper Torque Specifications for E-Bike Components

Beyond motor torque, proper assembly torque specifications ensure safe and reliable e-bike operation. Critical components require specific torque values during installation and maintenance. Bicycle maintenance standards provide guidelines for component assembly torque specifications.

Key torque specifications include: stem bolts (4-8 Nm), handlebar clamps (4-6 Nm), brake caliper mounting (6-8 Nm), and wheel axle nuts (30-40 Nm depending on axle type). Following manufacturer specifications prevents component failure and ensures optimal performance.

Motor Maintenance and Torque Performance

Regular maintenance preserves motor torque output and extends operational life. Maintenance protocols include cleaning electrical connections, checking mounting bolt torque, and monitoring motor temperature during operation. Proper maintenance ensures consistent torque delivery and prevents performance degradation.

Scheduled maintenance intervals depend on usage intensity and environmental conditions. Commercial applications and high-mileage riders require more frequent maintenance to maintain optimal torque performance and system reliability.

Future Developments in E-Bike Torque Technology

Emerging Motor Technologies

Advancing motor technologies promise improved torque density, enhanced efficiency, and reduced weight. Developments in permanent magnet materials, stator design, and control algorithms continue to push the boundaries of e-bike motor performance. Future Movcan models will incorporate these advances to deliver superior torque characteristics.

Emerging technologies include direct-drive systems with improved efficiency, lightweight materials that reduce motor weight without sacrificing torque output, and smart control systems that learn rider preferences and optimize torque delivery accordingly.

Integration with Smart Systems

Future e-bike systems will integrate torque control with GPS navigation, weather data, and route planning to optimize performance proactively. These intelligent systems will adjust torque characteristics based on anticipated terrain and riding conditions, maximizing efficiency and rider satisfaction.

Smart integration enables predictive torque management, automated performance optimization, and seamless connectivity with mobile devices and fitness tracking systems. This represents the next evolution in e-bike technology sophistication.

Conclusion: Choosing the Right Torque Specifications

Selecting optimal torque specifications requires careful consideration of riding style, terrain requirements, and performance expectations. The Movcan lineup offers carefully engineered torque characteristics across all models, ensuring every rider finds their perfect match. From efficient urban commuting to extreme off-road adventures, proper torque specification transforms the riding experience.

Understanding motor torque empowers informed decisions that maximize satisfaction and performance. Whether prioritizing efficiency for daily commuting or seeking maximum capability for recreational adventures, torque specifications directly impact every aspect of the riding experience. The investment in proper torque engineering pays dividends in improved performance, enhanced safety, and extended enjoyment of electric bike ownership.

Ready to experience the difference that properly engineered motor torque makes? Explore the complete Movcan e-bike collection and discover models optimized for your specific riding requirements. From precision-tuned commuter bikes to high-performance mountain machines, find your perfect torque specification today.

Share:

Top 10 E-Bike Friendly Cities in the US - Your Ultimate Urban Cycling Guide

Dual Control Systems: Advanced E-Bike Control Technology